My Garage

My Account

Cart

Genuine Toyota Land Cruiser Clutch Slave Cylinder

- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

9 Clutch Slave Cylinders found

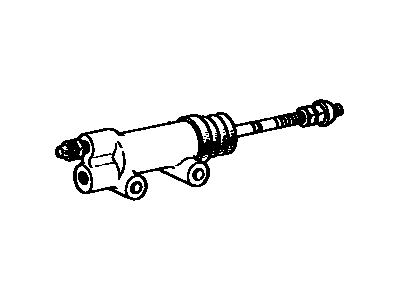

Toyota Land Cruiser Clutch Release Cylinder Assembly

Part Number: 31470-60071$82.35 MSRP: $116.09You Save: $33.74 (30%)Toyota Land Cruiser Clutch Release Cylinder Assembly

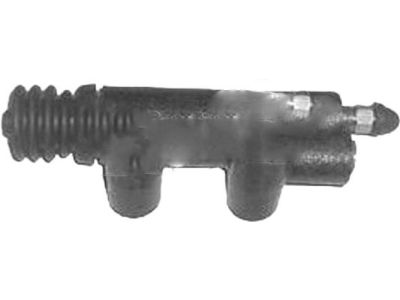

Part Number: 31470-60101$90.61 MSRP: $127.73You Save: $37.12 (30%)Ships in 1-3 Business DaysToyota Land Cruiser Clutch Release Cylinder Assembly

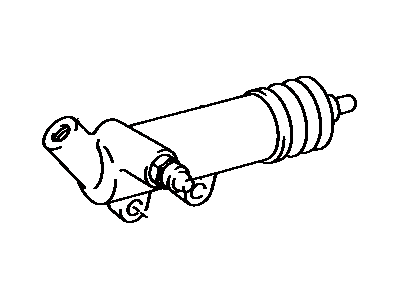

Part Number: 31470-60100$18.45 MSRP: $26.05You Save: $7.60 (30%)Toyota Land Cruiser Clutch Release Cylinder Assembly

Part Number: 31470-60081$82.35 MSRP: $116.09You Save: $33.74 (30%)

Toyota Land Cruiser Clutch Slave Cylinder

If you are in demand for superior quality and affordable OEM Toyota Land Cruiser Clutch Slave Cylinder, then shop with us! We own a wide range of the reduced-priced genuine Toyota Land Cruiser Clutch Slave Cylinder. You can purchase in confidence as all parts come with a manufacturer's warranty. Any issues with our products? No need to worry as we have a hassle-free return policy to guide you every step of the way.

Toyota Land Cruiser Clutch Slave Cylinder Parts Questions & Experts Answers

- Q: How to remove, overhaul, and install a Clutch Slave Cylinder on a Toyota Land Cruiser?A:Before beginning this procedure, contact local parts stores and dealer service departments concerning the purchase of a rebuild kit or a new clutch slave cylinder, as the availability and cost of the necessary parts may dictate whether the cylinder is rebuilt or replaced with a new one. If you decide to rebuild the cylinder, inspect the bore. Disconnect the cable from the negative terminal of the battery, raise the vehicle and support it securely on jackstands, then disconnect the hydraulic line at the clutch slave cylinder using a flare-nut wrench to prevent rounding off the fitting, while having a small can and rags handy for any spilled fluid. Remove the clutch slave cylinder mounting bolts and then the clutch slave cylinder itself. For the overhaul, take out the pushrod and the boot, tap the cylinder on a block of wood to eject the piston and seal, and remove the spring from inside the cylinder. Inspect the bore for deep scratches, score marks, and ridges, ensuring it is smooth to the touch; if any imperfections are found, replace the clutch slave cylinder with a new one. Using the new parts from the rebuild kit, assemble the components with plenty of fresh brake fluid for lubrication, noting the installed direction of the spring and seal. For installation, place the clutch slave cylinder on the clutch housing, ensuring the pushrod is seated in the release fork pocket, then connect the hydraulic line to the clutch slave cylinder and tighten the connection. Fill the Clutch Master Cylinder with brake fluid conforming to DOT 3 specifications and bleed the system. Finally, lower the vehicle and reconnect the cable to the negative terminal of the battery.

Related Toyota Land Cruiser Parts

Browse by Year

1987 Clutch Slave Cylinder 1986 Clutch Slave Cylinder 1985 Clutch Slave Cylinder 1984 Clutch Slave Cylinder 1983 Clutch Slave Cylinder 1982 Clutch Slave Cylinder 1981 Clutch Slave Cylinder 1980 Clutch Slave Cylinder 1979 Clutch Slave Cylinder 1978 Clutch Slave Cylinder 1977 Clutch Slave Cylinder 1976 Clutch Slave Cylinder 1975 Clutch Slave Cylinder 1974 Clutch Slave Cylinder 1973 Clutch Slave Cylinder 1972 Clutch Slave Cylinder 1971 Clutch Slave Cylinder 1970 Clutch Slave Cylinder 1969 Clutch Slave Cylinder