My Garage

My Account

Cart

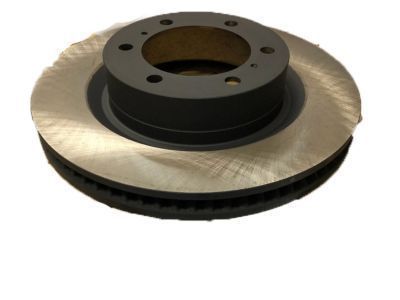

Genuine Toyota Brake Disc

Disc Rotor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

324 Brake Discs found

Toyota Disc Brake Rotor Front

Part Number: 43512-60191$76.45 MSRP: $107.76You Save: $31.31 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Disc, Front; Rotor

- Position: Front

- Replaces: 43512-60190

- Product Specifications

- Other Name: Rotor, Brake Front ; Disc, Front; Rotor

- Manufacturer Note: MEXICO SPEC

- Position: Front

- Replaces: 43512-06090

Toyota Rear Rotor

Part Number: 42431-60311$84.36 MSRP: $118.91You Save: $34.55 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Disc, Rear; Rotor

- Position: Rear

- Product Specifications

- Other Name: Rotor, Brake Front ; Disc, Front; Rotor

- Position: Front

- Product Specifications

- Other Name: Disc, Front; Rotor

- Position: Front

- Replaces: 43512-04051, 43512-04050

Toyota Disc Brake Rotor Front

Part Number: 43512-0C011$84.12 MSRP: $118.58You Save: $34.46 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Disc, Front; Rotor

- Position: Front

- Replaces: 43512-0C010

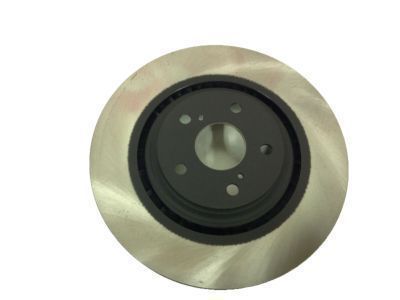

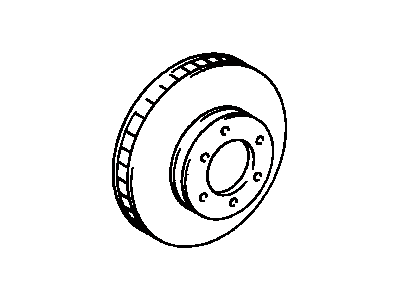

Toyota Rear Disc

Part Number: 42431-0E020$71.50 MSRP: $100.78You Save: $29.28 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Rotor, Brake Rear ; Disc, Rear; Rotor

- Position: Rear

Toyota Disc Brake Rotor Front

Part Number: 43512-06200$71.26 MSRP: $100.45You Save: $29.19 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Disc, Front; Rotor

- Position: Front

- Product Specifications

- Other Name: Rotor, Brake Front ; Disc, Front; Rotor

- Position: Front

- Replaces: 43512-42090, 43512-02250, 43512-42050

Toyota Disc Brake Rotor Front

Part Number: 43512-02240$62.29 MSRP: $87.81You Save: $25.52 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Disc, Front; Brake Rotor, Rotor

- Position: Front

- Replaces: 43512-12710

- Product Specifications

- Other Name: Disc, Rear; Rotor

- Position: Rear

- Replaces: 42431-0C010

Toyota Rear Disc

Part Number: 42431-42060$59.21 MSRP: $82.77You Save: $23.56 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Disc, Rear; Rotor

- Position: Rear

Toyota Rear Disc Brake Rotor

Part Number: 42431-60201$88.49 MSRP: $124.73You Save: $36.24 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Disc, Rear; Rotor

- Position: Rear

- Replaces: 42431-60200

Toyota Disc Brake Rotor Front

Part Number: 43512-35210$72.68 MSRP: $102.44You Save: $29.76 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Disc, Front; Rotor

- Position: Front

Toyota Rear Disc

Part Number: 42431-12310$59.70 MSRP: $84.15You Save: $24.45 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Disc, Rear; Rotor

- Manufacturer Note: PARKING BRAKE-CENTER LEVER(CHROME PLATING KNOB)

- Position: Rear

- Replaces: 42431-02200

Toyota Disc Brake Rotor Front

Part Number: 43512-42040$67.84 MSRP: $95.62You Save: $27.78 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Disc, Front; Rotor

- Position: Front

- Replaced by: 43512-0R010

- Replaces: 43512-42080

Toyota Rear Disc

Part Number: 42431-60290$93.80 MSRP: $132.22You Save: $38.42 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Disc, Rear; Rotor

- Position: Rear

Toyota Rear Disc

Part Number: 42431-0R010$59.21 MSRP: $82.77You Save: $23.56 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Rotor, Brake Rear ; Disc, Rear; Rotor

- Position: Rear

- Replaced by: 42431-42060

- Product Specifications

- Other Name: Rotor, Brake Rear ; Disc, Rear; Rotor

- Position: Rear

- Product Specifications

- Other Name: Disc, Front; Rotor

- Position: Front

| Page 1 of 17 |Next >

1-20 of 324 Results

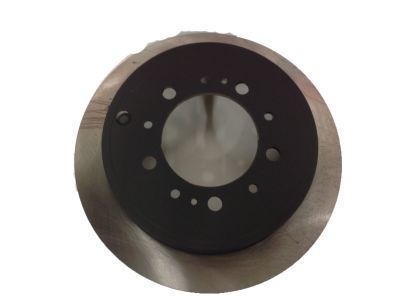

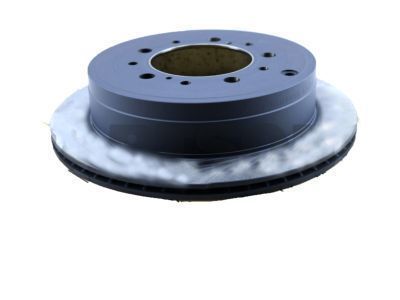

About Toyota Brake Disc

The Toyota brake disc rotor is designed with the brake pad set to dissipate heat from the braking system, and to stop your vehicle. While your wheel is rotating, the brake disc is removing excess heat from the braking system until it has to be used to slow or stop your Toyota. When the brake disc is in excellent working order, you will be able to precisely stop your Toyota to avoid any potential accidents or hazardous situations. You will find a brake disc securely attached to each wheel of the disc braking system.

However, after thousands of miles of driving, the brake disc rotor can become warped and lose its friction surface. In order to replace the brake disc, remove the wheel, remove the brake caliper, remove the brake pads and hardware, then remove your brake disc and replace it with your new parts after thoroughly cleaning the brake dust off with brake cleaner. If your brake disc rotor becomes too warped, you will lose a lot of braking ability and may not be able to stop in time when you need to. Brake discs usually can be resurfaced once before it will need to be replaced with a new one.

Here is a piece of good news that you do not need to struggle for OEM or aftermarket parts for your Toyota anymore. Since you are able to buy the perfectly-fit Toyota genuine part by spending less money, why do you insist on aftermarket parts? We present you a massive selection of Toyota OEM parts with an affordable price, so that you can make your shopping process ends at ToyotaPartsDeal.com. You can find everything you are looking for here and be surprised by the competitive price. Besides all of above, we have a wonderful after-sale service that you can return the part without any hassle.

However, after thousands of miles of driving, the brake disc rotor can become warped and lose its friction surface. In order to replace the brake disc, remove the wheel, remove the brake caliper, remove the brake pads and hardware, then remove your brake disc and replace it with your new parts after thoroughly cleaning the brake dust off with brake cleaner. If your brake disc rotor becomes too warped, you will lose a lot of braking ability and may not be able to stop in time when you need to. Brake discs usually can be resurfaced once before it will need to be replaced with a new one.

Here is a piece of good news that you do not need to struggle for OEM or aftermarket parts for your Toyota anymore. Since you are able to buy the perfectly-fit Toyota genuine part by spending less money, why do you insist on aftermarket parts? We present you a massive selection of Toyota OEM parts with an affordable price, so that you can make your shopping process ends at ToyotaPartsDeal.com. You can find everything you are looking for here and be surprised by the competitive price. Besides all of above, we have a wonderful after-sale service that you can return the part without any hassle.

Toyota Brake Disc Parts Questions & Experts Answers

- Q: How to inspect, remove, and refit a rear brake disc on Toyota Yaris?A:Chock the front wheels, then jack up the rear of the vehicle and support it on axle stands before removing the rear roadwheels. Detach the rear brake caliper from the disc without disconnecting the flexible hose, and support the caliper on an axle stand or suspend it with wire to avoid straining the hose. Temporarily refit two wheel nuts to diagonally-opposite studs with the flat sides against the disc and tighten them progressively to hold the disc firmly. Scrape any corrosion from the disc, rotate it, and examine for deep scoring, grooving, or cracks, measuring the thickness in several places with a micrometer; the minimum thickness is stamped on the disc hub. Light wear and scoring are normal, but excessive wear requires removal for regrinding or replacement, ensuring the minimum thickness is maintained, and cracked discs must be renewed. Check the disc run-out 10 mm from the outer edge using a dial gauge or flat metal block and feeler gauges, ensuring it does not exceed the specified limit by fixing the measuring equipment and rotating the disc to note measurement variations. If the run-out is excessive, check for variations in disc thickness by marking the disc at eight positions 45° apart and measuring the thickness 15 mm in from the outer edge; if the variation exceeds the specified amount, the disc should be renewed. The hub face run-out can also be checked by removing the disc, fixing the measuring equipment, and rotating the hub to ensure the run-out does not exceed the specified amount; excessive run-out should be corrected by renewing the hub bearings before rechecking the disc run-out. With the wheel and caliper removed, take off the temporarily refitted wheel nuts, mark the disc in relation to the hub if it is to be refitted, and remove the washer/retaining clip(s) if fitted, then withdraw the disc over the wheel studs. Ensure the disc and hub mating surfaces are clean, locate the disc on the wheel studs, and align the previously made marks if the original disc is being refitted. Refit the washer/retaining clip(s) if applicable, then reattach the brake caliper and carrier bracket, followed by the wheel. Lower the car to the ground and tighten the wheel nuts to their specified torque, then test the brakes carefully before returning the car to normal service.

Related Toyota Parts

Browse by Model

4Runner Brake Disc 86 Brake Disc Avalon Brake Disc C-HR Brake Disc Camry Brake Disc Celica Brake Disc Corolla Brake Disc Corolla Cross Brake Disc Corolla iM Brake Disc Corona Brake Disc Cressida Brake Disc Crown Brake Disc Echo Brake Disc FJ Cruiser Brake Disc GR Corolla Brake Disc GR Supra Brake Disc GR86 Brake Disc Grand Highlander Brake Disc Highlander Brake Disc Land Cruiser Brake Disc MR2 Brake Disc MR2 Spyder Brake Disc Matrix Brake Disc Mirai Brake Disc Paseo Brake Disc Pickup Brake Disc Previa Brake Disc Prius AWD-e Brake Disc Prius Brake Disc Prius C Brake Disc Prius Prime Brake Disc Prius V Brake Disc RAV4 Brake Disc RAV4 Prime Brake Disc Sequoia Brake Disc Sienna Brake Disc Solara Brake Disc Starlet Brake Disc Supra Brake Disc T100 Brake Disc Tacoma Brake Disc Tercel Brake Disc Tundra Brake Disc Van Brake Disc Venza Brake Disc Yaris Brake Disc Yaris iA Brake Disc bZ4X Brake Disc